Heating Systems Solutions

Whether farrowing, nursery or finishing, Lange Ag System offers a variety of heaters designed for swine facilities. These heaters improve swine productivity, reduce time to market, and lower operating costs of swine production.

L.B. White Classic Forced Air Heaters

The direct-fired L.B. White Classic forced air heater is a reliable pilot ignition design that pig producers have relied on for over 40 years. Classic pig building heaters provide consistent, dependable heat that helps control pig house climate. Classic forced air heaters with pilot ignition can be used in all swine production environments and phases including gestation, nursery, and wean-to-finish.

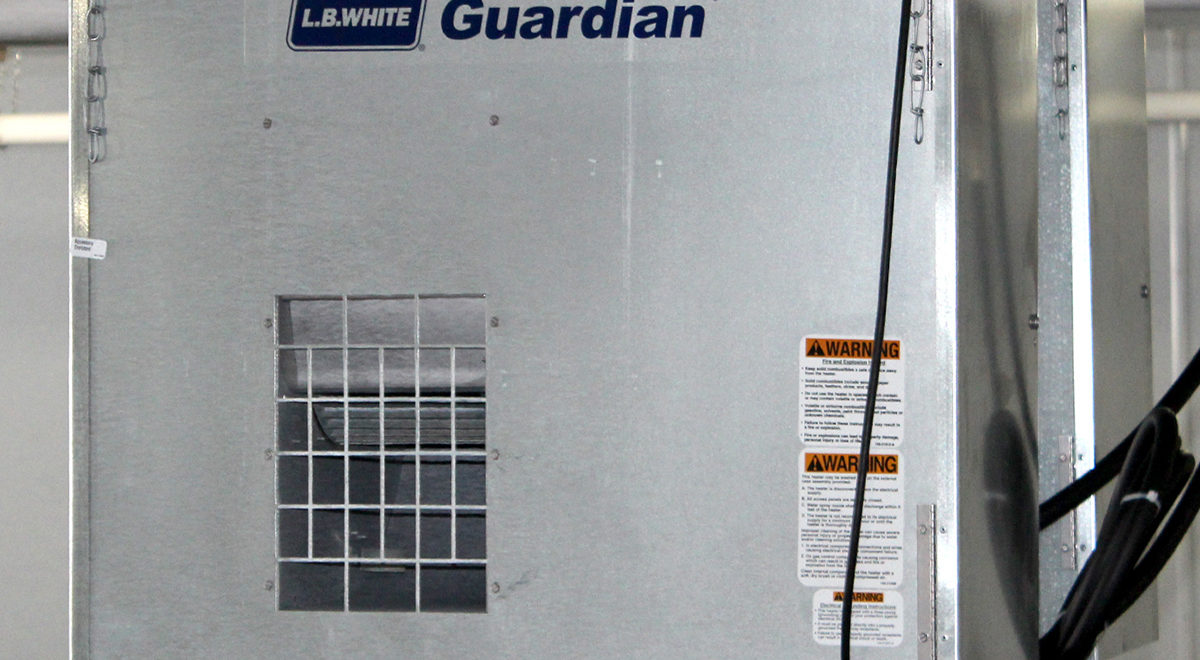

L.B. White Guardian Forced Air Heaters

The direct-fired L.B. White Guardian® is designed to protect pig producers’ investments when the weather turns cold. Guardian® pig building heaters provide consistent, dependable heat that helps control pig house climate. Guardian® heaters can be used in all swine production environments and phases including gestation, nursery, and wean-to-finish.

LB White Radiant Brooder Heaters

Improve animal welfare, production, and profitability in pig complexes with our unique high pressure radiant brooder heaters. This radiant heat pig brooder leads the industry in heat efficiency, range of heat outputs, flexible installation and proven reliability. L.B. White designed our brooders to save money on energy costs – up to 40% fuel cost savings depending on the facility condition and existing pig heating system.

L.B. White Smart Sense Heaters

Smart Sense® is a technologically-advanced swine facility heating solution. This innovative heating technology eliminates the inefficiency of standard on/off controls by managing the heat automatically through the house control. Smart Sense® operates at maximum efficiency to provide fuel-cost savings up to 35%, consistent room temperature, enhanced animal welfare and improved air quality.

Better Air Exchangers

The Better Air Exchanger automatically exchanges humid, stale air from inside the garage or shop with an equal amount of fresh outside air. Two air streams enter the unit’s core where they pass by each other, but do not mix since the individual aluminum plates in the core keep them separate. The EXHAUST fan draws stale, moist air from inside the building into the unit before sending this air to the outside. The INTAKE fan simultaneously draws fresh, dry air from the outside into the unit where it passes between the aluminum plates taking on the heat from the exhausting stale air. The clean, dry, fresh heated air is then circulated into the shop. As it becomes stale, it is drawn into the Air Exchanger and the process is repeated.