Your Livestock Equipment, Construction, and Storage Solution Experts

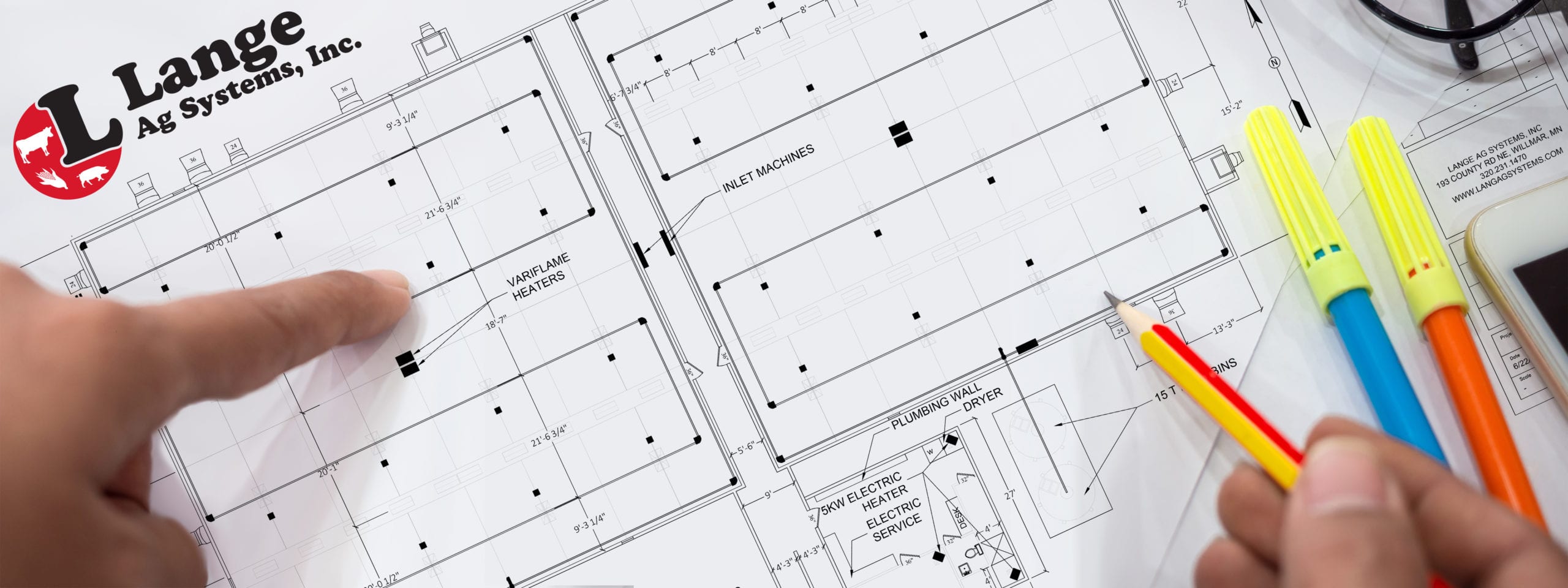

Latest Project

2400 Head Wean-To-Finish (101′ x 210′)

Lange Ag Solution Specialists

Take pride in helping you before, during, and after your project is complete.

Getting Your Barns Ready For Winter

Keeping your hogs at the right temperature is vital for a productive operation. And since we…

Join us at these upcoming 2025 Trade Shows!

South Dakota Pork Congress Sioux Falls Ramkota Hotel & Exhibit Hall • Sioux Falls, SDWednesday, January…

Continue Reading Join us at these upcoming 2025 Trade Shows!

Creating The Ideal Pig Environment

What does it take to create the perfect environment for pigs? The primary goal is to…

Partnering with the Industry’s Best Manufacturers